Table of Contents

If you’ve been around a job site lately, you’ve probably heard someone mention machine control. Maybe it was on a dozer, maybe on a skid steer or excavator. But what is it, really?

Here’s a straight answer, written plain and simple—no fancy talk.

What Is Machine Control?

Machine control is a system that helps your equipment know where it is on the site—and how much dirt it needs to move—without the operator guessing. It uses GPS and a 3D model of the job to guide the machine.

Instead of depending on stakes or lasers, the machine follows a digital map that tells it where to cut or fill. The operator sees this map on a screen in the cab.

It’s like putting a GPS brain in your machine. And that’s helping a lot of folks get the job done faster and better.

It’s not just about automation—it’s about giving your crew better tools to work smarter, safer, and more accurately.

Why Are More Contractors Using It?

Here are 7 real reasons:

1. You Save Time

With machine control, there’s no stopping to check grades or run string lines. Operators can stay in the seat and keep working. That means more work done every day. Time is money on every job, and machine control gives you more of both.

2. It’s More Accurate

You don’t have to guess where grade is. The machine knows. It’s using GPS coordinates and the model to put every pass in the right place. That makes jobs smoother and cuts down on rework. You can trust the grade, even on complex pads or tight tie-ins.

3. You Use Less Material

If you over-cut, you’ve got to haul in more fill. If you over-fill, you waste material. Machine control keeps you right on grade, so you’re not paying for extra base rock, asphalt, or haul-off. That adds up quick, especially on commercial or subdivision jobs.

4. Better for New Operators

You don’t need a 20-year veteran to hit finish grade. With machine control, even less experienced operators can work with confidence. That helps you train faster and move people where you need them. You get more flexibility on the crew and better results.

5. Fewer Layout Mistakes

Stakes get knocked over. Paint fades. People misread plans. With a digital model in the machine, you take the guesswork out of layout. What the model says is what the machine does. That consistency makes a big difference when you’re on a tight timeline.

6. Works on All Kinds of Jobs

Machine control isn’t just for highways or huge subdivisions. It’s great for house pads, parking lots, school sites, public works, and even utility trenching. Anywhere dirt needs to move with precision, machine control makes the job smoother.

7. It Helps You Win Bids

When you can trust your quantities, your cuts and fills, and your grading time—you can bid tighter. That gives you an edge over the competition without risking your profit. You can also show up on bid day with better data, which makes a difference when owners ask questions.

Real Jobsite Example:

On a recent school site, a contractor used machine control on a finish dozer to dial in the pad grade. The site had tight slopes around sidewalks, multiple building pads, and tight drainage features. Using the model, they avoided staking delays and cut finish grading time by three days.

Another crew on the same site used GPS on a compact track loader with a grading box to fine-grade curb returns. No need for extra stakes or grade checking—just smooth, finished subgrade that passed inspection on the first round.

No busted curb grades. No guesswork. Just clean, precise finish work from a model that told the machine what to do.

Bonus: What You Need to Get Started

Thinking about trying machine control? Here’s what you need:

- A good GPS system (like Trimble, Topcon, or Leica)

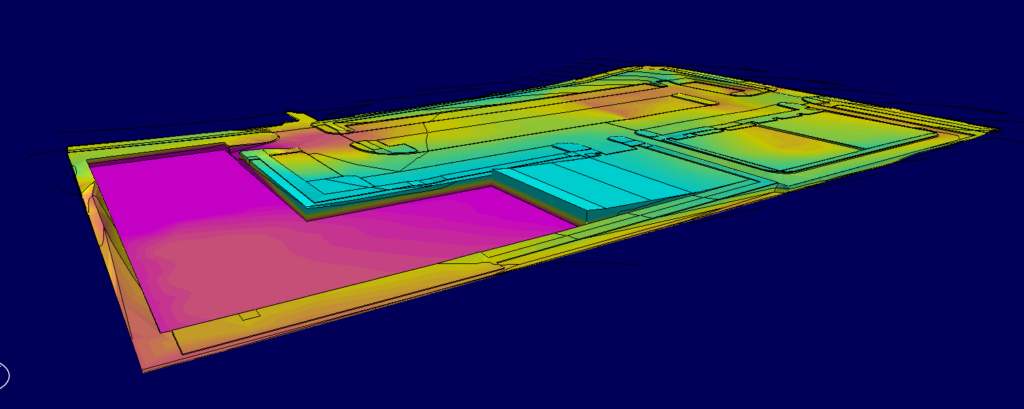

- A solid 3D model built specifically for your job

- Operators willing to learn (they don’t need to be experts)

- Support from a company like TCL Consulting to help you get set up with the right file

Machine control works best when the model is accurate, clean, and built to match your plans. That’s where we come in. We build models that match your grading intent so you can trust what the blade is doing.

Final Thoughts

Machine control is changing how dirt gets moved. It’s not just for the big companies anymore.

It’s for every contractor who wants to be faster, cleaner, and more efficient—whether you’re building a house pad or a 100-acre site.

It’s more than a fancy tool. It’s a better way to work.